August 26, 2025

The Vostochny gold mine – kinda traditional; but these days – completely digital.

Hi folks!

Been a while, yes, but – you know: August! :). Meanwhile – rewind: back to July…

I’ve said this many times, but I’ll say it again: practically all industrial facilities – quarries and mines, power plants and factories, trucks and ships – are permeated through and through with all kinds of cyber-technologies. Indeed, the only non-digitized operation I’ve seen in the last 10 years or so is… the production of coconut oil in Fiji! :).

And since the prefix “cyber-” is, alas, increasingly more often followed by “-incident”, the combination of “cyber + security” is also becoming increasingly popular and in-demand – including at industrial facilities. It’s for this very reason we work closely with a wide variety of manufacturing companies. Over the years, such partnerships have become more and more based on trust – and with that comes our being invited to visit production sites to see how things actually work. And that’s what happened on our July trip to Krasnoyarsk (which I gave a brief summary of in my last post a month ago): We express our appreciation of and respect for our clients, and at the same time satisfy our own curiosity. After all, it truly is very, very interesting to see up close different lesser-known aspects of just how this world really ticks! Not on a TV screen sat in the office or on the couch at home – but in person and live: from a front-row seat and with full immersion, so to speak.

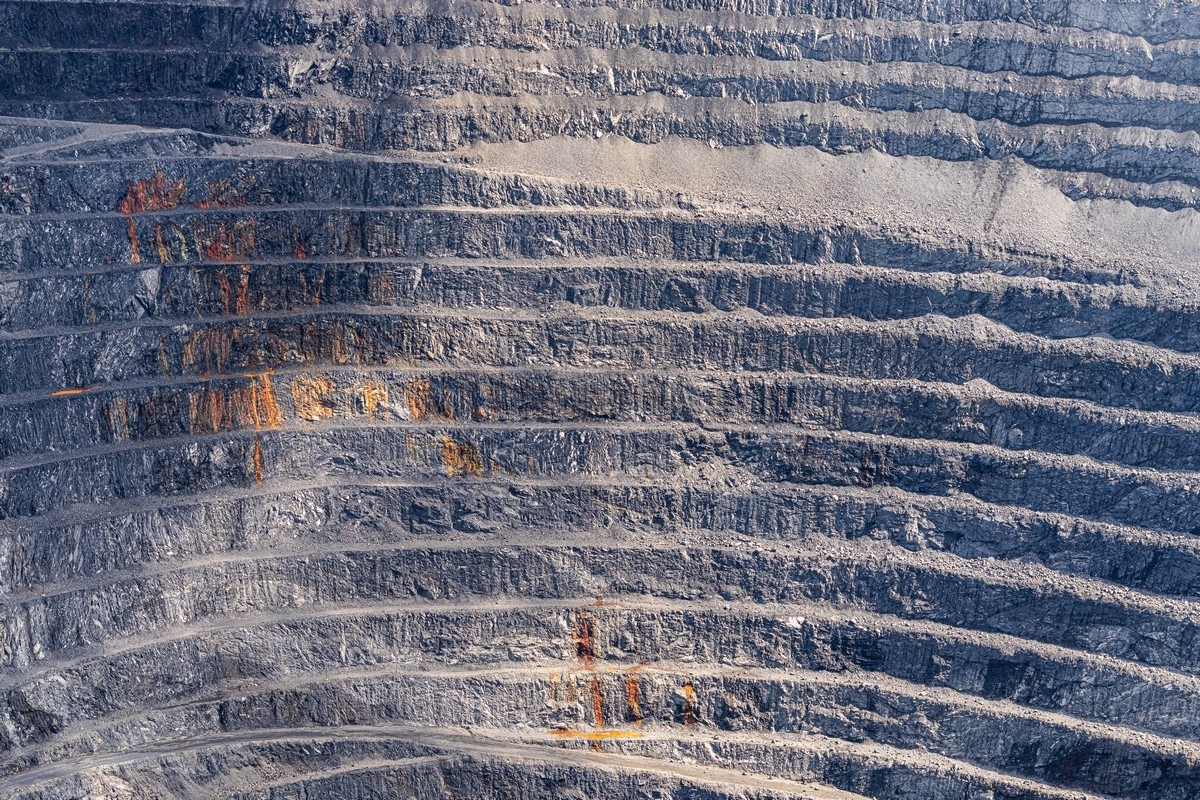

In just three days we managed to visit a whole five sites – the first of which was the Vostochny (“Eastern”) open-pit mine, where the company Polyus (pronounced pOl-yoos) mines gold. And since this quarry is one of the deepest in the world (more precisely, the second deepest – after the US’s Bingham Canyon Mine), it was doubly interesting to see this man-made wonder with our own eyes:

This is what the mine looks like from up above:

An impressive structure!

The quarry is an almost perfect cone some 880 meters deep, while Bingham Canyon is 1200m; however, as the company’s management told me, with a few more years of mining, it should overtake Bingham to become the world’s deepest – unless, of course, it’s beaten by Chile’s Chuquicamata (currently 850m+). Let’s wait and see…

The width of the Vostochny quarry across the top is about 1800m. Gulp. Nearly two kilometers wide! :O)

Oh – and here are four record certificates earned by Vostochny from the Russian Book of Records:

So, let’s go check it out it with our own eyes…

Impressive…

Mining is done in layers: they blast the next section down (to crush the rock) and then haul it away for processing in massive heavy-duty dump trucks. And so it goes on in a cycle further and further down…

These “tiny” dump trucks haul the mined rock up to the enrichment and processing workshops. However, if you count from the previous photos, there are more than 20 levels in the quarry – which means each “step” is about 40 meters high! You can draw your own conclusions about the size of the dump trucks!

Yes, they’re big:

And up close:

A humongous thing! This particular dump truck has a payload capacity of (I think) 240 tons! // I’ve always wondered: what would the nearest tire shop charge to change one of these beast’s tires? :)

And the platform on which the driver’s cab sits is called, in nautical fashion, the “deck”. I was told the same thing when I was in Belarus.

The gold-mining process begins with a controlled explosion. Yep – one’s scheduled over there in two-minutes’ time… ->

Curiously, since the explosion is taking place more than a kilometer away from us, the column of smoke from the explosion appears completely silently. Only after a couple seconds does the sound reach us: BOOM! ->

The mined rock is then taken away for processing, where it goes through several stages of enrichment (much like how I described the process following my visit to the Nordgold plant in 2018). Not that we had time for visiting the production workshops on this trip. We were only shown the final stage of the process – the casting of 900 – one nine fine gold bars (they’re sent somewhere else for further refining and finishing).

The gold starts pouring…

A fresh ingot cools down:

And another one:

This is what the plant’s finished product looks like:

Yes – it’s heavy!

And the waste rock is dumped on slag heaps:

“But where’s all the cyber-stuff?” you might ask. It’s simply everywhere! Virtually everything is digitized, monitored, and controlled. Every excavator, every dump truck – its location is known, whether it’s working or being repaired, and so on. The condition of the quarry itself is also monitored separately: temperature, ground subsidence, and so on – in order to predict landslides and other collapses and prevent emergencies. And that’s why we’re very respected guests here :)

And a huge thank-you for the warm welcome!

And what a lunch they fed us here! A true gastronomic delight :)

That isn’t a picture in a frame – the dish is just presented that way. You have to tear off the “picture” – and there’s food underneath. The “picture” itself is also edible :)

After lunch it was on to our next stop – in this ->

PS: Answers to potential questions.

1. In photo #2, you can see that the bottom of the quarry is flooded with water. What gives?

Yes, this is a normal phenomenon in quarries and open-pit mines. Pumping water out of such facilities is a normal part of the production process.

2. What brand are the trucks?

I don’t remember. Caterpillars I think, but I’m not sure. There is a rumor that they’re planning to buy Chinese trucks, because (again, I’m not sure and could be wrong) the BelAZ trucks can’t handle such significant changes in elevation.

3. How much gold does the enterprise produce?

60 tons a year!

4. Where’s the site located?

Around 430km north of Krasnoyarsk.

And that’s all for today folks; back soon!…