September 5, 2025

The impossibly gigantic bucket-wheel excavator of Nazarovsky open-pit mine.

Still back in July, still back in Krasnoyarsk Krai, next up on our tour of our dear heavy-industrial customers’ operations (after the Vostochny Gold Mine, the Boguchany Aluminum Smelting Plant, and the Boguchany Dam) – another two industrial giants – the Nazárovsky and Beryózovsky coal mines, which both belong to Siberian Coal Energy Company (SUEK). And just like at the other industrial facilities in Krasnoyarsk Krai, the way we were welcomed was as if we were royalty!

// I say royalty – but only… tee-totaling royalty! At every industrial site in Russia that I’ve visited over the past 10–15 years, a no-alcohol rule is strictly enforced – even for visitors. At every entrance (and exit (!)), employees/ workers/ miners all take a breathalyzer test; if the result‘s positive – immediate dismissal. Apparently, way back when this rule first came in (some time in last century), there was initial resistance: “Come on, how can we work without Alexey? He’s a drunkard, sure – but he’s still a master of his trade”. But no: other – sober – Alexeys were found to replace drunk Alexeys. So yes, back to our welcome: it was grand, but there was nothing stronger than fruit juice on the tables!

But enough of the industrial-site sobriety – let me show you the photos. They’re mixed in from both mines. Just to whet your appetite…

Photo 1, Nazarovsky:

Photo 2, Beryozovsky:

Here we go!…

SUEK is the largest coal company in Russia, and one of the largest in the world. It operates eight underground mines and 19 open pits (I checked this online). We were lucky enough to visit two pits, both part of SUEK-Krasnoyarsk (this subsidiary runs three in total). And this year SUEK-Krasnoyarsk has proudly shipped its two-billionth ton of coal! Woah. I wondered – and asked: what would two billion tons of coal look like physically? And they had an answer for me! -> “If you loaded all that coal onto the wagons of [an impossibly long] single train, it would wrap around the globe almost 10 times!“

Altogether, SUEK mines around 110 million tons of coal per year. So how long would a year’s-worth train be? But it’s not so simple: different cars have different capacities. So I dug around online: coal is usually transported in cars carrying on average 65 tons each. That means about 1.7 million cars per year. Each car is roughly 14 meters long, so the total length would be about 23,000km – and after you add in all the locomotives needed: closer to 25,000km) That’s more than half the length of Earth’s equator! Oh my gasp–gulp!

But I’m rambling again – back to the photos. Here’s one from the Nazarovsky pit:

Now, a bit about how coal is mined in an open pit.

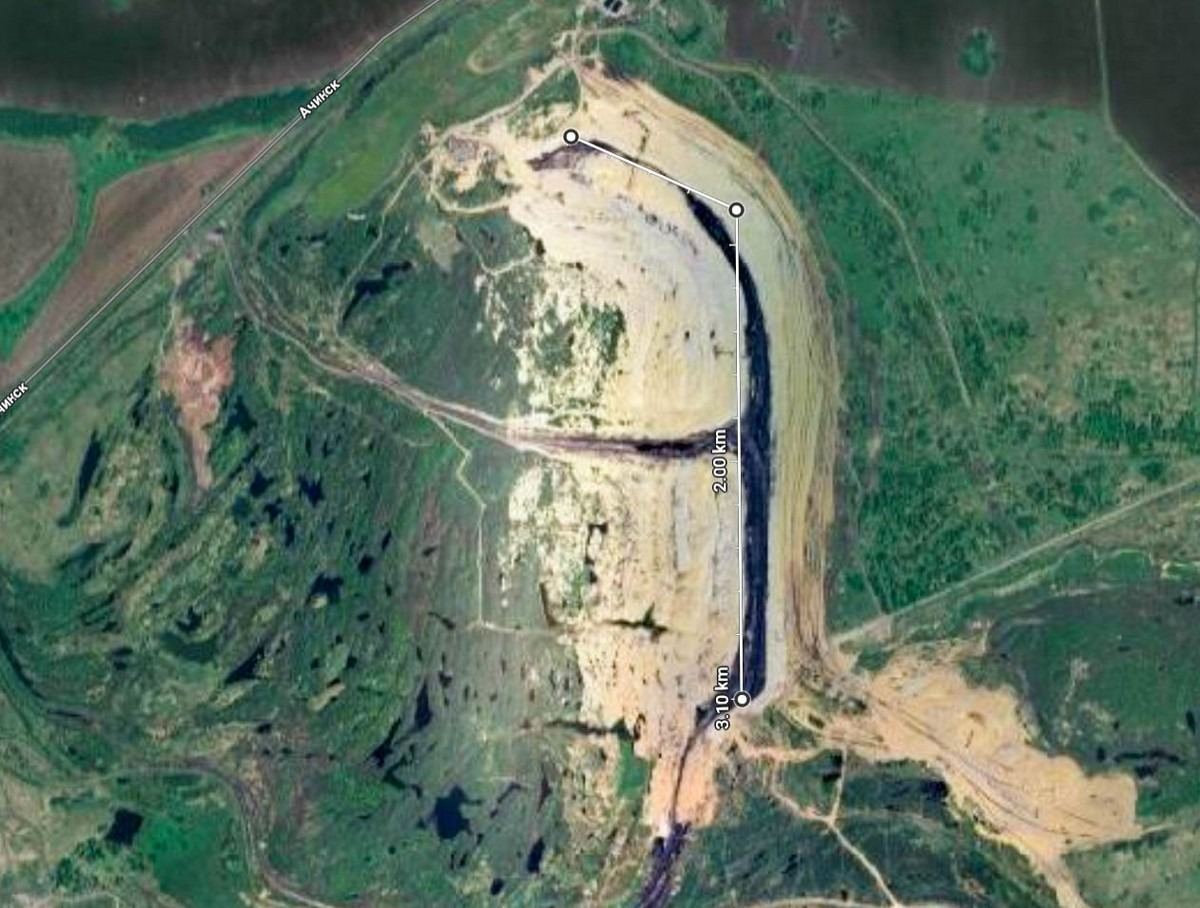

A coal seam (about 15m thick) lies under a 70-meter layer of barren rock (the mining term is “overburden”). So before the coal is mined, the overburden has to be stripped away and dumped, then the coal layer is extracted and shipped by rail, then the next layer of cover is removed – and so on, in cycles. This pit is basically a 3km-long coal-mining line, with waste dumps on one side and untouched land (with coal underneath) on the other. And the line slowly moves eastward:

They cover the dumps with fertile soil, which they then grass over – so the land eventually regains its original appearance.

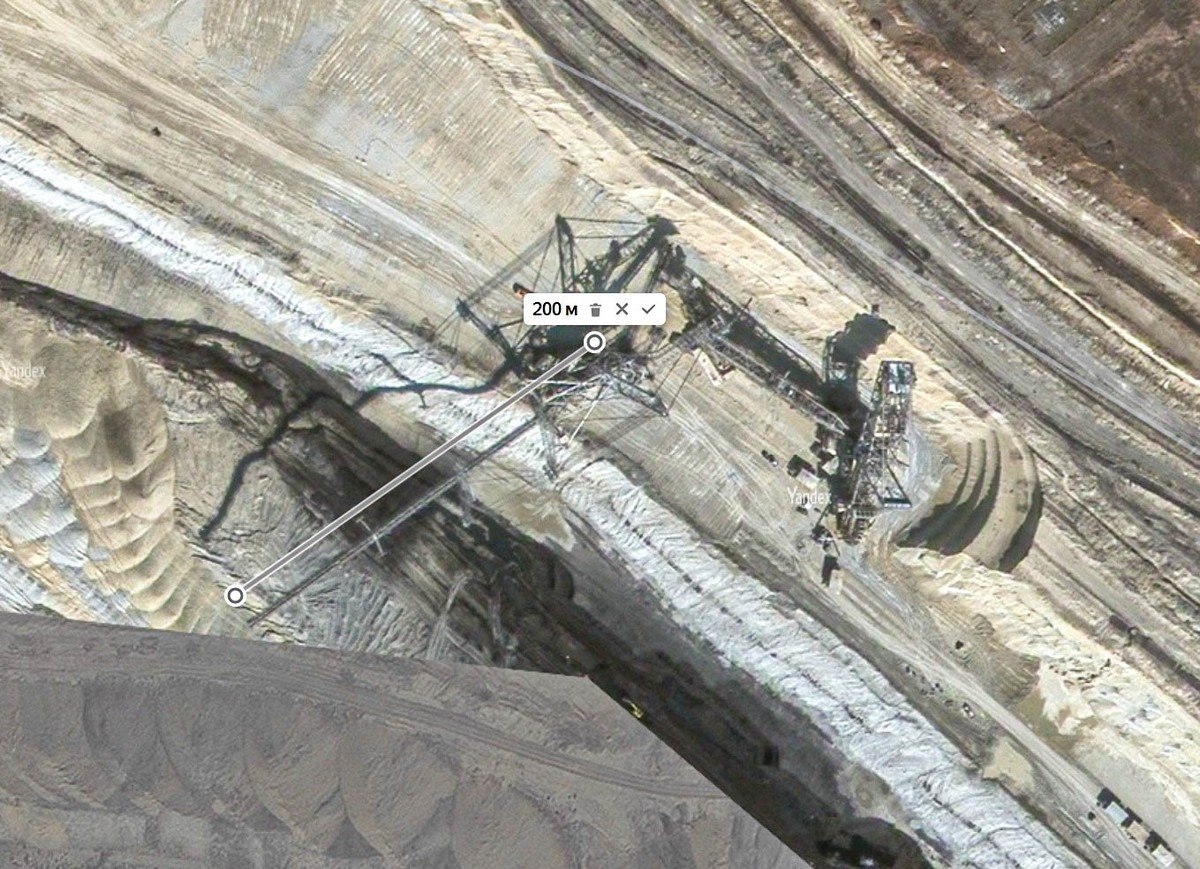

But the real showstopper here is the gigantic bucket-wheel excavator, which strips away the overburden and dumps it via a conveyor belt onto the waste pile. This thing is so massive that, up close, even a wide-angle lens can’t fit it in! To capture the whole machine you need to shoot from afar or from the air:

The bucket-wheel excavator consists of three linked machines: a rotary excavator + a reloader + a spreader. The excavator (machine #1) digs and sends rock along a conveyor to the reloader (machine #2), which connects to the spreader (machine #3), which then lays it all out in dumps. The reloader is essential, since the excavator moves gradually along the pit, and it’d be impractical to drag the entire complex behind it. So they came up with this “three-joint linkage”.

Some more specs of this beast:

- Height: over 70m (a little taller than London’s Tower Bridge)

- Overall length: nearly 500m (half a kilometer!)

- Total weight: almost 10,000 tons (the same as… the Eiffel Tower!)

- Rotary wheel diameter: 16m (a five-story building!)

- Each track: 13m long, 4m wide (that’s just one track!)

- Conveyor belt length (reloader): ~200m

The rotary wheel has 24 buckets, each holding 2300 liters. The whole system has five conveyor belts, which together can move material 420m. The rock travels from pit to dump in around two minutes. The complex processes over 4000 cubic meters per hour, run by a crew of 56 workers.

A monster-excavator!

To get a sense of the scale… ->

Only two such complexes have ever been built in the world, produced at the (formerly) East German TAKRAF factory:

The Nazarovsky mine received its complex in 1986 – and it took a full three years to assemble it!

Now for a walk around this monster. The excavator’s operated from here. While it was originally a mostly analogue beast, everything’s long since been digitized-computerized:

The rotary wheel with buckets. Again, its diameter is a whopping 16 meters!

And in just two minutes, the excavated rock ends up all the way over there:

Here’s the whole process, from the start. First, removing the overburden ->

The conveyor sends it to the reloader ->

Which is itself no small machine! ->

Then the 200-meter boom flings it into the dump:

Some of these shots aren’t just massive – the colors make them look almost otherworldly…

Again: the scale’s just mind-blowing. Look carefully to spot the people in this photo:

So far we’ve toured the “overburden” level, but the coal mining takes place a level below:

Aerial shots. The graveyard of decommissioned machinery:

The whole pit:

The dumps: fresh and reclaimed, already overgrown with shrubbery:

And some more:

That’s the area we just walked through:

Btw: nearby is the Nazarovo Power Plant – one of the main consumers of the coal mined here:

And that was that. Onward we fly!…